If the plant is doing the heating method, most likely the plant has a steam-system involved in that method. Meaning, the plant is utilizing a large boiler and a group of carbon steel pipes working through the entire plant. It essential to protect the plant’s investment from thermal, scale shock damage, and oxygen pitting. Not following this formula can lead to expensive repairs and multiple shutdowns if you don’t make the plant system free from corrosion.

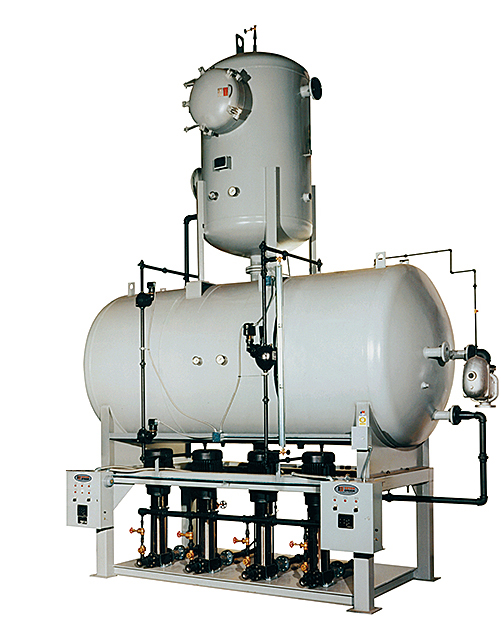

If the plant is operating a steam system, it has at least one deaerator like tray type deaerator that can make any industrial task easier for the workers. If the plant is planning to utilize a new system, it’s crucial to know and balance the value of that particular component.

In other cases, a plant should ensure that the deaeration process receives the constant limelight it deserves, not only for the long-term capability of the system but for the efficient of the process as well.

Know the Importance of Deaeration for Boiler Feedwater

Deaerator gathers and re-heats all the returned condensate that came from the steam system. This returned condensate is combined with softened water that chemically tends to dissolve oxygen, non-condensable gases, and carbon dioxide from the water formula before it’s going to be pumped on the large tank (boiler).

Chemically treated makeup water and return condensate is essential to make your boiler, steam traps, and steel piping free from corrosion. It is happening because of the oxygen content present in the water, getting too many amounts of those water before it returns is mandatory.

While these methods look like long-term maintenance, it’s essential to know that the usual repair could shut down any plants for a month, and may vary depending on the size of the boiler. So, these lengthy downtime is a hassle and stressful, especially for the workers. That’s why deaeration is made to control and manage the most steam system to become more efficient and reliable.

The Influence of Freshwater to Boiler Feedwater

The Influence of Freshwater to Boiler Feedwater

Freshwater or also known as makeup water is an essential element to make the deaeration process efficient. Aside from understanding the actual process, it is also vital to see the boiler feed qualities.

Hard water as one of the example is lime that will plate out on the tubes, pressure, and piping – this can lead with two issues: limits the steam system efficiency by reducing the heat transfers, and tube failures due to hot spots on the tubes.

As the process continues to work, the scale flakes from the pipes tend to seize in the stream traps. It makes the appearance of a clay-like element that can topple them over time.

For example, the boiler has a 0% returned condensate, which is called as the “worst,” you’ll need 100% of the feedwater. These values are incredibly inefficient because they’ll need to re-heat the water and use a more substantial amount of the boiler’s energy. In other cases, for example, a 0% returned condensate, it’ll be needing additional chemicals to create a defense and balanced the pH level; which is expensive and time-consuming.